Many well-known businesses whose brands have become household names (think 3M, Clorox, Vanish, and more) have teams of skilled chemical engineers working behind the scenes to create the products we all use and love.

Those teams are the backbone of any production operation, ensuring processes run smoothly, safely, and efficiently.

But finding and hiring the best chemical engineer can be daunting. With many candidates to choose from, you might ask yourself, “How do I know who is the best fit for my business? How do I assess their skills? What interview questions should I ask chemical engineers?”

Many other questions need answers to help you navigate the sea of resumes, cover letters, and profiles. In this article, we’ll walk you through the essential steps of hiring a chemical engineer.

We’ll identify the hard and soft skills vital for success in the field. Also, you’ll find a chemical-engineer job description template to attract top talent. Further, we’ll discuss different ways to assess a candidate’s suitability for the role, including pre-screening tests and interviews.

Finally, we’ll also introduce assessments to help you find the best chemical engineer for your company.

Table of contents

- What is a chemical engineer?

- Chemical engineer hard skills

- Chemical engineer soft skills

- How to test chemical engineer skills

- In-house employees vs contractors

- Where to find chemical engineers

- Chemical engineer job description template

- How much does a chemical engineer cost?

- Chemical engineer interview questions

- Revamp your recruitment with TestGorilla

What is a chemical engineer?

Chemical engineers are professionals who apply scientific principles to design, develop, and optimize industrial processes. They use these processes to produce various products, from fuels to consumer goods.

Chemical engineers work in various industries, like chemical manufacturing, energy, and materials science. Usually, they are responsible for creating sustainable and efficient solutions to complex problems.

Their job involves using their knowledge of chemical processes, thermodynamics, and fluid mechanics to develop new products, improve existing processes, and minimize waste and environmental impact.

They may work on smaller or large-scale projects. An example is the design and construction of chemical plants or the development of new energy sources.

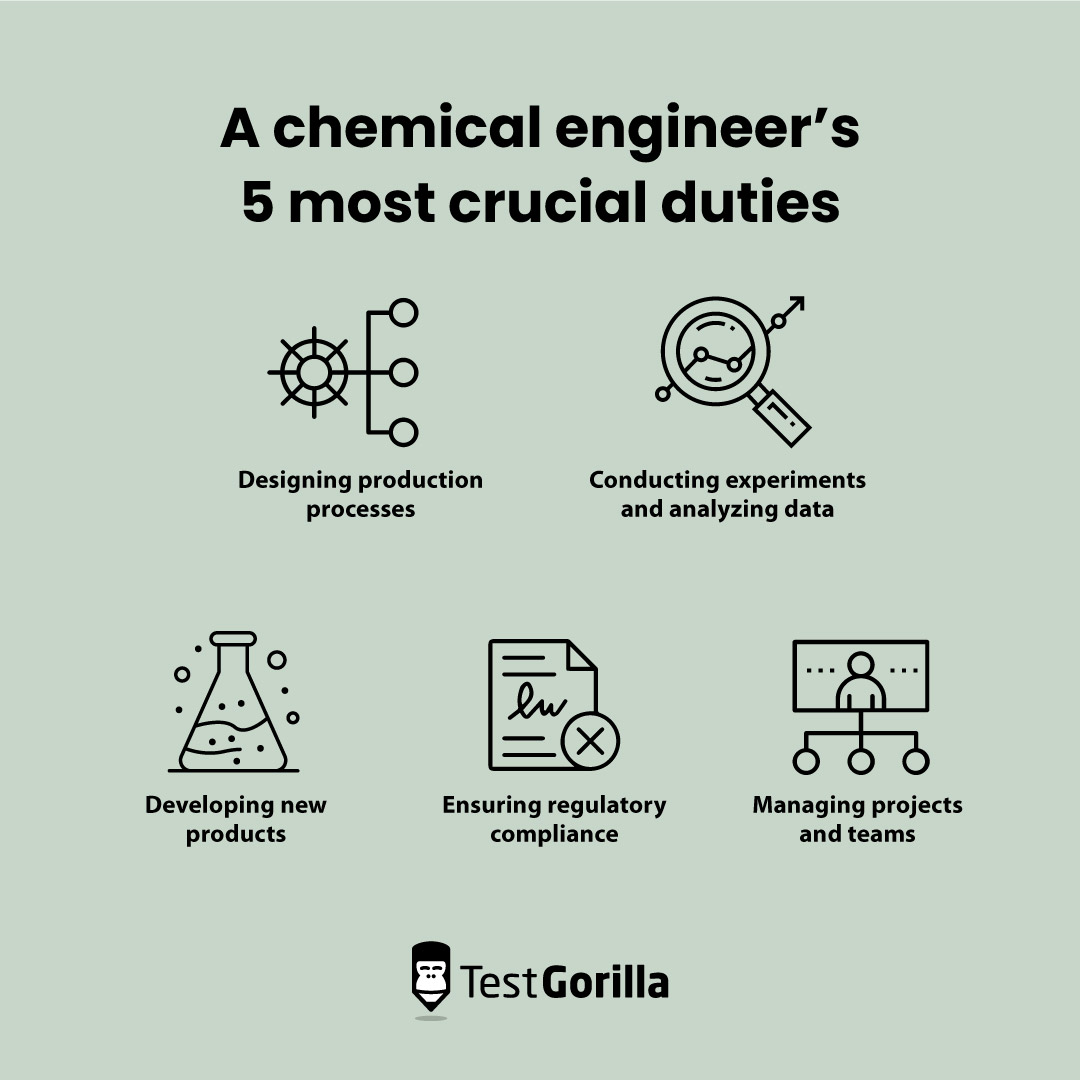

Chemical engineers have a diverse set of responsibilities; here are five of their most crucial duties:

Designing production processes: Chemical engineers use their expertise to design, develop, and optimize production processes that are efficient, safe, and environmentally friendly.

Conducting experiments and analyzing data: They conduct experiments to test and improve production methods and equipment. They do this by using data analysis and statistical tools to interpret the results.

Developing new products: Chemical engineers also play a vital role in researching and developing new products, from the initial conception to the final stages of full-scale production.

Ensuring regulatory compliance: These experts certify that their processes and products meet regulatory and safety standards. Also, they can work closely with regulatory agencies to obtain necessary approvals.

Managing projects and teams: Chemical engineers often lead projects and teams. They work with other experts like scientists, production managers, and chemists to achieve common goals. Also, they may manage timelines, budgets, and resources.

Chemical engineer hard skills

For a role as technical as chemical engineering, candidates need strong technical competencies and hard skills to excel.

Take Jane, for example. She’s a chemical engineer and had to design a process to extract a rare mineral from a new source. The pressure was on her to deliver results.

As she reviewed the data, her mind raced with complex math and physics equations and the intricate interplay of chemical reactions. With her deep technical knowledge and skills, Jane knew it’d take all of her hard skills to crack the code and unlock the mineral’s secrets – which she did after a few failed attempts.

Here are five of the chemical engineer hard skills she used for the project:

1. Process design and simulation skills

Chemical engineers use their knowledge of processes, equipment, and flow diagrams to design and optimize industrial processes. An example is the production of chemicals, fuels, or pharmaceuticals.

Simulation software like Aspen HYSYS allows them to create computer models of these processes. They can use the simulation to predict the process’ behavior under different conditions. Then they optimize them to cut costs and improve environmental efficiency.

For example, they might use simulation to optimize a chemical reactor. The purpose might be to maximize yield or reduce the energy required to produce a chemical.

2. Materials science and engineering skills

Chemical engineers require a good understanding of materials science and engineering principles to choose suitable materials for different applications. For example, they select the right type of plastic for a car dashboard that is heat-resistant, strong, and lightweight.

Also, they might need to choose a suitable metal alloy for a strong, corrosion-resistant car engine with good thermal conductivity to dissipate heat and sunlight.

3. Process control and instrumentation skills

Chemical engineers design and implement control systems to optimize industrial processes and certify their safety. They use sensors to measure process variables like pressure, temperature, and flow rate. This data helps them adjust process parameters in real time.

For example, they might use a temperature sensor and a PID (proportional–integral–derivative) control algorithm to maintain a consistent temperature in a chemical reactor. Also, they can use a flow meter and a control valve to regulate the fluid flow rate in a pipeline.

4. Computational modeling and data-analysis skills

Chemical engineers use MATLAB, Python, or R software tools to analyze and process data and build models to solve problems. This helps them optimize processes, predict process behaviors under different conditions, and troubleshoot issues.

For instance, they may use data from chemical processes to develop models that predict the concentration of compounds over time. Interestingly, they can use statistical analysis to identify trends or patterns in the data.

5. Knowledge of safety and environmental regulations

Chemical engineers should be familiar with safety and environmental policies to guarantee that their processes comply with current regulatory requirements. Regulations may be subject to occasional modifications, so chemical engineers should stay abreast of such changes.

For example, they may need to design a chemical process to minimize the release of toxic or flammable materials. Further, they may create safety systems like pressure relief valves or emergency shutdown systems to protect workers and the environment.

They also need to comply with regulations such as the Clean Air Act or the Clean Water Act from the US EPA. These acts limit the amount of pollutants released into the environment from industrial processes.

The best insights on HR and recruitment, delivered to your inbox.

Biweekly updates. No spam. Unsubscribe any time.

Chemical engineer soft skills

It takes a number of technical and non-technical skills to make a complete expert: Soft skills are essential for efficient teamwork, collaboration, and problem-solving.

Having the right soft skills enables chemical engineers to overcome even the most daunting problems in the lab and beyond, which is why developing them through education, training, and experience is essential for career success.

Here are five of the most impactful soft skills to look for in a chemical engineer:

1. Communication skills

Chemical engineers should be able to communicate technical information to non-technical stakeholders like managers, clients, or representatives from regulatory agencies. This skill also helps them work with experts from other fields, like chemists, physicists, or mechanical engineers.

Communication skills prove helpful in chemical engineering when professionals need to:

Present process designs or results of simulations to management or other stakeholders

Collaborate with chemists or other scientists to design experiments or interpret results

Write technical reports or documentation to communicate project progress or results to team members or clients

2. Critical thinking and problem-solving skills

It’s important for chemical engineers to analyze complex problems, identify potential solutions, and evaluate each possible method’s feasibility and impact. They also need to be able to make decisions based on incomplete or uncertain information.

Critical thinking and problem-solving skills are essential when chemical engineers need to:

Troubleshoot problems in a chemical process, such as low yield or product quality issues

Analyze data from experiments or simulations to identify trends or patterns

Evaluate the feasibility and cost-effectiveness of alternative process designs or equipment

3. Adaptability skills

Chemical engineers need to adapt to changing project requirements, technology, or market conditions. They also need to learn new skills or knowledge continuously.

For example, chemical engineers need to be flexible when they:

Deal with changes in process requirements, such as changing feedstock or product specifications

Learn new software tools or analytical techniques to solve a specific problem or support a new project

Work on multiple projects simultaneously and shift priorities when necessary

4. Attention-to-detail skills

It’s vital for chemical engineers to pay close attention to details because it allows them to make sure their processes or experiments are accurate and consistent. It also enables them to identify and correct errors or anomalies in data.

Chemical engineers need strong attention to detail to:

Check process instrumentation or equipment to confirm that everything is functioning correctly

Conduct experiments with precise measurements and control variables to guarantee accurate results

Review data from experiments or simulations to identify errors or inconsistencies

5. Leadership and teamwork skills

Most often, chemical engineers work in a group setting and should be able to contribute to team efforts effectively. They also need to be able to mentor or train junior engineers or technicians.

They can also be project leaders, responsible for supervising the project from start to finish. To perform their role, they delegate tasks and responsibilities and monitor their performance to meet due dates and budget requirements.

Chemical engineers need strong leadership skills when they need to:

Lead a project team to develop a new process or improve an existing one

Collaborate with colleagues from different disciplines to design and execute experiments

Mentor junior engineers or technicians to develop new skills and knowledge

How to test chemical engineer skills

Pre-employment testing has become popular among employers – and for a good reason. These modern tests objectively measure a candidate’s knowledge and experience in a given area. In addition, they provide you with valuable data to inform your hiring decisions.

Skill tests – like the ones we offer at TestGorilla – are objective and standardized, allowing you to assess candidates on the same criteria. Also, they reduce the risk of unconscious bias, which can often creep into traditional hiring processes.

By using these skill assessments, you can gain a deeper understanding of a candidate’s hard and soft skills and learn whether they fit with your organization’s culture and values. All these can help you identify candidates who best match any role you need.

TestGorilla is a robust pre-employment skills testing platform that offers a wide range of tests to help you simplify recruitment. Our test library includes tests for technical skills, personality traits, cognitive abilities, situational judgment, and language proficiency.

By leveraging the power of pre-employment testing, you can create a truly successful and efficient hiring process.

To hire your next chemical engineer, here are seven of our best tests that you can use before the interview stage:

1. GHS Safety test

Chemical engineers need to be well-versed in safety practices and have a strong understanding of the Globally Harmonized System of Classification and Labeling Chemicals (GHS).

You can assess your applicants’ GHS knowledge with the GHS Safety test, which evaluates their ability to:

Use the GHS effectively

Create a safe working environment

Maintain the safe transport, storage, and disposal of chemicals

Respond to accidents

2. Problem-Solving test

This test measures a candidate’s ability to solve complex problems using critical thinking and analytical skills. It helps evaluate a candidate’s ability to identify and analyze issues related to processes and develop practical solutions, and you can use it as a part of your chemical engineer recruitment process.

Use our Problem-Solving test to assess candidates’ abilities to apply logic, create schedules, prioritize tasks, and analyze textual and numerical data to derive information.

3. Communication test

This test assesses a candidate’s communication skills, including written and verbal communication. It can help evaluate a candidate’s ability to communicate complex technical concepts effectively to colleagues, clients, and stakeholders.

Further, our Communication test examines a candidate’s ability to use professional etiquette. It also tests candidates on non-verbal cues and active listening, which are part of an effective communication process.

4. Attention to Detail test

Chemical engineers need to be able to quickly spot and correct errors in documents, such as process flow diagrams, equipment specifications, and safety plans. To assess these skills, you can use our Attention to Detail tests, which can also help evaluate a candidate’s detailing and quality control skills.

You can use our Attention to detail (visual) or Attention to detail (textual) test to assess applicants. Both tests enable you to identify candidates that can thoroughly and attentively check details and make sure their work is error-free.

5. Data Analysis test

Use our Exploratory Data Analysis test to assess a candidate’s ability to gain insights from data by analyzing and interpreting it, for example by using statistical software like Excel, R, or MATLAB. This way, you can check their ability to use data to make informed decisions and optimize chemical processes.

We also have a Working with Data test that evaluates candidates’ ability to work with data to derive actionable and reliable results.

6. Time Management test

This test measures candidates’ ability to prioritize tasks, manage their time effectively, and meet project deadlines.

Our Time Management test uses typical workplace scenarios to evaluate candidates on their planning, prioritization, and project execution. It also assesses whether candidates can reflect on their work, monitor the outcome, and manage distractions.

7. Spatial Reasoning test

Having spatial reasoning skills is crucial for any professional in a STEM-related job (science, technology, engineering, and math).

Our Spatial Reasoning test assesses candidates’ skills in mental rotation, mental folding, spatial working memory, and spatial visualization. It helps you identify candidates that can analyze 2-dimensional and 3-dimensional objects in space.

In-house employees vs contractors

Finding the right chemical engineer for your project can be challenging, especially if you’re unsure where to begin your search. However, there are different channels you can explore to find the best candidates.

First off, consider the type of employment that suits your project: a standard employment contract or a contractor arrangement. Let’s look at their pros and cons:

1. In-house employees

One of the most common ways to hire chemical engineers, alongside other professionals, is as in-house employees. This option can offer several advantages, such as:

Full dedication to your projects: In-house employees can fully dedicate themselves to your organization and provide a high support level for each of your projects.

Strong company culture: Hiring in-house employees can help you build a strong company culture and a cohesive team.

Greater control: With in-house employees, you have greater control over their work and output.

However, there are also some potential downsides to hiring in-house employees, such as:

Higher costs: In-house employees generally come at a higher cost because you need to consider not just salaries but also benefits and overhead costs.

Limited expertise: Your company may not be able to hire all the specialized skills it needs in-house. This can limit the types of projects you can take on.

Long-term commitment: Hiring in-house employees is a long-term commitment, which may not be suitable for all projects.

2. Contractors

Alternatively, you can consider hiring chemical engineers as contractors or consultants. This form can offer some unique advantages, such as:

Cost savings: Contractors may cost less compared to hiring in-house employees because you can hire them on a project basis and you don’t have any associated overhead costs.

Greater flexibility: With contractors, you can have more flexibility and adapt to project timelines better. This is especially helpful if your needs are fluctuating.

Access to specialized expertise: Contractors may offer specialized expertise in niche areas of chemical engineering that your organization may not have in-house.

Also, there are some potential downsides to hiring freelancers:

Limited control: It might be more demanding to manage and supervise contractors compared to in-house employees.

Cultural fit: Contractual employees may not fit as well into your organization’s culture and may not be as invested in the success of your organization.

Short-term commitment: Contractor work is usually short-term, which may not be suitable for projects requiring long-term employee support or collaboration.

Depending on your business needs, you can choose the one that suits you best.

Where to find chemical engineers

So, where can you find skilled and experienced chemical engineers for your company? Here are some of the best options:

1. Professional organizations

Several professional organizations and associations for chemical engineers exist, such as the American Institute of Chemical Engineers (AIChE) and the Institution of Chemical Engineers (IChemE).

These organizations can be an excellent resource for finding potential hires or connecting with other professionals in the field.

2. LinkedIn

LinkedIn is a valuable tool for finding chemical engineers. You can search for candidates based on their job titles, experience, education, and other criteria, and then can connect with them to discuss job opportunities.

3. University career centers

Many universities with chemical-engineering programs have career centers and job programs you can explore. You can use the platform to connect with fresh graduates or alumni eager to find work in the field.

4. Job boards

Several job boards cater specifically to the engineering and technology sectors, like EngineerJobs. These job boards can be an excellent platform to post job listings or search for potential candidates.

5. Referrals

Word-of-mouth referrals from colleagues, business partners, or industry contacts are also an excellent way to find chemical engineers. Contact your professional network to see if anyone can recommend potential candidates.

Chemical engineer job description template

Well-written job descriptions are essential when hiring for a new role. They contain all the key details: the job role, requirements, qualifications, company summary, and other information to attract the best talent for the job. Additionally, they come with the following benefits:

Job descriptions provide clarity: Job descriptions make it easy for employers and potential candidates to understand the job and make sure their expectations are aligned.

They help with standardization: Writing a job description for each new opening guarantees that all job postings are consistent across different roles and departments. This creates a level playing field for all applicants and promotes fairness in the hiring process.

They attract high-quality candidates: A well-written job description can attract the best candidates and motivate them to apply. It also helps potential candidates determine if they qualify for the position.

They help with legal compliance: A job description helps you ensure you comply with legal requirements and include all information required by law. For example, you need to add EEO statements to prevent legal issues relating to discrimination.

Here are some of the best practices to consider when writing your next job description:

Clearly define the position

Outline the key responsibilities

Identify the required qualifications

Emphasize the desired soft skills

Discuss the company culture and values

Keep the language simple and concise

Learn how to prepare job descriptions for a skills-based hiring approach in our article on the topic.

See the example below of a job description template:

[Job title]

[Formal position title]

Reports to: The [job title] will report to [positions title or titles this position reports to].

Job Overview: [A brief, detailed description of the position, what it entails to be successful, and how it fits into the company.]

Responsibilities and duties:

List the vital tasks needed to carry out the job according to priority.

Use complete sentences.

Start sentences with verbs.

Speak in the present tense.

Use gender-neutral language.

Qualifications:

[Required education level]

[Required experience]

[Preferred education level]

[Preferred experience]

How much does a chemical engineer cost?

When hiring a chemical engineer in the US, the cost can vary depending on various factors. According to the US Bureau of Labor Statistics, the median chemical engineer salary in the United States was $105,550 per year in 2021.

Factors that determine the annual salary include the location, industry, and the candidate’s experience level. For example, chemical engineers in the pharmaceutical manufacturing industry may earn higher salaries than others.

On the other hand, states with a higher cost of living may have higher average salaries for chemical engineers. According to data from Zippia, the top-paying region for chemical engineers in the US is Sugar Land. There, the average salary in 2021 was $114,407 yearly.

Keep in mind, however, that it’s vital to consider the entire remuneration package and not just the salary. Additional expenses include employee benefits, insurance, training, and other costs for recruitment, onboarding, and retention.

Consider all these factors when budgeting to hire a chemical engineer. This guarantees you can attract and retain top talent while staying within budget.

Chemical engineer interview questions

Interviews are a vital part of any hiring process. It helps employers assess a candidate’s technical knowledge, problem-solving skills, and ability to work in a team. There are several interview types to explore when interviewing chemical engineer candidates.

1. Behavioral interview

This interview helps you learn how the candidate behaved in the past and how they may behave in their next job. Questions focus on how candidates handled specific situations, pressure, challenges, or conflicts in previous roles.

It’s an excellent way to gain insights into a candidate’s work style and identify their strengths and weaknesses. However, it might prove ineffective if candidates lie.

2. Technical interviews

Technical interviews assess a candidate’s knowledge and skills in chemical engineering. Interview questions should focus on core engineering principles and expertise in the field.

It’s handy for assessing a candidate’s suitability for specific technical roles. However, conducting it may be challenging, as you may require a deep understanding of the subject yourself. It can also help to identify candidates that didn’t prepare for the process.

3. Panel interviews

Panel interviews involve multiple interviewers or a hiring team questioning a candidate simultaneously. The interviewers can be from different departments, and their questions may cover various topics, including technical, behavioral, and cultural fit.

It provides a broader perspective and insights from different angles. Also, it assesses how the candidate may fit into the company’s culture. Some candidates might, however, feel intimidated when interviewed by a hiring team.

Regardless of the option you choose, equip yourself with credible questions before the interview. Here are five interview questions to ask a candidate for a chemical-engineer role:

Can you describe your experience with chemical process design and optimization?

How do you approach problems in your work as a chemical engineer?

Can you explain your experience with process safety management and regulatory compliance?

Can you give an example of a project you worked on and how you contributed to the project’s success?

How do you stay up to date with the latest developments and trends in the chemical engineering industry?

Revamp your recruitment with TestGorilla

Before you start looking for your next chemical engineer, identify the critical skills and qualifications for the role which you need to assess. Pre-screening tests are a great way to do that, as they provide you with reliable and objective data on candidates’ skills.

Additionally, using pre-screening tests can save time and resources and reduce the risk of making a bad hire. Simply check the results to see who your best applicants are and invite them to an interview.

If you need a reliable pre-screening test platform to hire chemical engineers, TestGorilla is your best bet. Our platform is user-friendly, secure, and provides detailed reports to help you make informed hiring decisions. Sign up for free to get started and take the first step toward hiring the perfect match.

For more insights on how to hire engineers, read our guide on strategies for how to recruit engineers.

You've scrolled this far

Why not try TestGorilla for free, and see what happens when you put skills first.