Safety and efficiency are two key reasons why equipment maintenance should be carried out regularly by skilled maintenance technicians.

However, if you are hiring maintenance workers and don’t have much knowledge about the role (or of heavy equipment management), how do you know if your candidates have the essential maintenance technician skills to do the job successfully?

The fastest and most accurate way to do this is with our Equipment Maintenance test.

When used at the start of your hiring process and coupled with well-thought-out interview questions for the top-scoring candidates, our maintenance worker test will provide you with the hard data that can help you make more informed hiring decisions.

We’re going to look at how this test can screen your candidates for the right level of maintenance technician skills, and how it can be combined with other job-related skills tests to create a full pre-employment assessment.

First, let’s focus on the essential skills maintenance technicians need to ensure industrial machinery is both safe and running efficiently.

Maintenance technician skills

As with most jobs, the required skills can be broken down into two main categories – technical skills and soft skills.

Some employers make the mistake of focusing on only the technical equipment skills when hiring a maintenance technician. It’s easy to assume that applicants already possess enough soft skills to get by, or that soft skills don’t matter much for the role they are hiring for.

However, both sets of skills are essential for job success, as we shall see in the following sections.

Technical skills

The range of technical skills for a maintenance worker will vary according to the specific job role and duties, but technicians should have these core job skills:

Broad technical knowledge

This is, arguably, the most important of the maintenance technician skills. They must possess a working knowledge of hydraulic, pneumatic, mechanical, and electrical systems, as well as a familiarity with inspections.

It does depend on the job responsibilities and the employer, but mechanics are also often trained in the use of computer numeric control (CNC) machines and have proficiency in computer-aided drafting (CAD) programs.

Other technical skills include the ability to use a variety of power tools, hand tools, and other commonly-used devices in maintenance work. Some maintenance technicians also hold popular professional certifications such as the Commercial Driver License (CDL), or the OSHA Safety Certificate.

Computer skills

As technology evolves, so do job roles. Although technicians primarily work with machinery, it’s essential that they can use any specialized hardware or software, such as diagnostic tools for troubleshooting and computer maintenance management systems (CMMS).

Other important maintenance technician skills in computing include using email and messaging apps, and the ability to order what they need from supplier websites.

Math and physics skills

Maintenance workers use math every day in their jobs. Some essential math skills for technicians includes:

Arithmetic and algebra

Fractions

Decimals

Percentages

Ratios and proportions

Different systems of measurement

Geometry

Trigonometry

Other useful maintenance technician skills are:

Mechanics of materials

Thermodynamics

Calculus-based physics

Electrodynamics

Soft skills

There are a range of soft skills you can test for when it comes to hiring a good equipment maintenance technician:

Problem solving skills

Part of a technician’s job calls for the ability to find and resolve complex problems. Candidates need an aptitude for solving problems successfully (and quickly), in order to troubleshoot issues that arise on the job.

As well as collecting data and determining causes of failures, technicians need to be able to work out a stopgap solution in emergency situations.

TestGorilla’s Problem Solving test evaluates candidates to see which ones quickly identify the key elements of a problem and work through the problem at speed without making mistakes. This is a great test to include in an assessment alongside the Equipment Maintenance test to check candidates’ overall analytical skills.

Attention to Detail

All maintenance professionals know that missing or ignoring small problems can lead to massive issues further down the road.

There’s also the safety aspect to consider – if a technician skips steps or is lax about implementing lock-out tag-out (LOTO) safety procedures, it could lead to serious injuries or fatalities to the workers using the machine, or the equipment technicians themselves. The equipment maintenance technician role is considered to be one of America’s most dangerous.

Good maintenance technicians always ensure their work is compliant with OSHA maintenance standards and other regulatory requirements.

Our Attention to Detail (Textual) test evaluates candidates on their ability to process textual information and arrive at the correct answer without losing sight of small details that can have a big impact.

It’s a great test for all job roles to find applicants who are thorough in their work and take careful consideration of everything before coming to a conclusion, and it’s a useful way to help evaluate maintenance technician skills.

For a similar test that uses visual elements and information to assess candidates’ skills, we also have an Attention to Detail (Visual) test.

Communication Skills

Verbal and written communication is a key skill for an equipment maintenance technician. They must be able to relay and understand information on maintenance issues in a variety of formats, including phone or video calls, face-to-face, or by email or other textual communication.

Excellent communication skills can also help staff develop and maintain interpersonal relationships with coworkers and other industry professionals.

TestGorilla has developed a Communication test to evaluate how well candidates interact with others. Top scorers on this test have the ability to listen attentively to others, communicate with confidence and open-mindedness, and can offer empathy and feedback at the right place and time.

Critical thinking

Equipment technicians need to use their critical thinking skills in order to analyze blueprints and schematics. This soft skill can also help with troubleshooting issues and developing solutions. Our Critical Thinking test is suitable for many roles.

Those who do well on the Critical Thinking test tend to have a well-trained working memory. If you are looking for candidates who are independent thinkers, able to solve complex problems, generate innovative solutions and have good overall analytical skills, this test is a great place to start.

Physical Ability

Although this is not generally considered a soft skill as such, it’s an important area of equipment maintenance technician skills, because maintenance work is physically demanding.

Machinery may be situated in very hot or cold areas, or have tiny crawl spaces for technicians to work in. Maintenance workers must often carry and climb ladders, repeatedly use stairs, carry or drag heavy objects, and work for long periods of time in awkward positions.

Maintenance workers are often required to be bending, squatting, kneeling, and lying on the ground intermittently throughout the day. They may also need to wear a fall protection harness while working from heights or from a suspended position.

In addition to this, other essential maintenance technician skills are good hand-eye coordination and excellent eyesight.

Use our Equipment Maintenance test as part of a comprehensive pre-employment assessment

Although you can use our Equipment Maintenance test as a standalone, we recommend using it as part of a wider pre-employment assessment in order to gain more extensive data and insight into your candidates’ technical and soft skills. You can also evaluate them for personality traits and how well they might align with your organization’s values with our Culture Add test.

First, let’s take a closer look at the Equipment Maintenance test and how it’s designed to evaluate maintenance technician skills.

This test is written by a subject-matter expert with over three decades of international experience in engineering and heavy equipment management in the construction, oil and gas, mining, manufacturing, and marine fields.

It’s designed to appraise a candidate’s maintenance technician skills and abilities to comprehend, evaluate, and implement equipment maintenance for commonly encountered heavy equipment.

The Equipment Maintenance test focuses on three broad equipment categories: mechanical, hydraulic, and pneumatic, as well as electrical and electronic. The questions focus on understanding system function, testing, adjustment, diagnostics, and overhauling. The skills associated with inspections are also covered in this maintenance technician skills test, which includes understanding manuals as well as failure analysis.

This test is full of images and diagrams of machines, systems, and tools with which an intermediate technician should be familiar. These images are important because on-the-ground skills require visual literacy.

The machines chosen for the test questions contain core systems that all intermediate technicians should be able to evaluate.

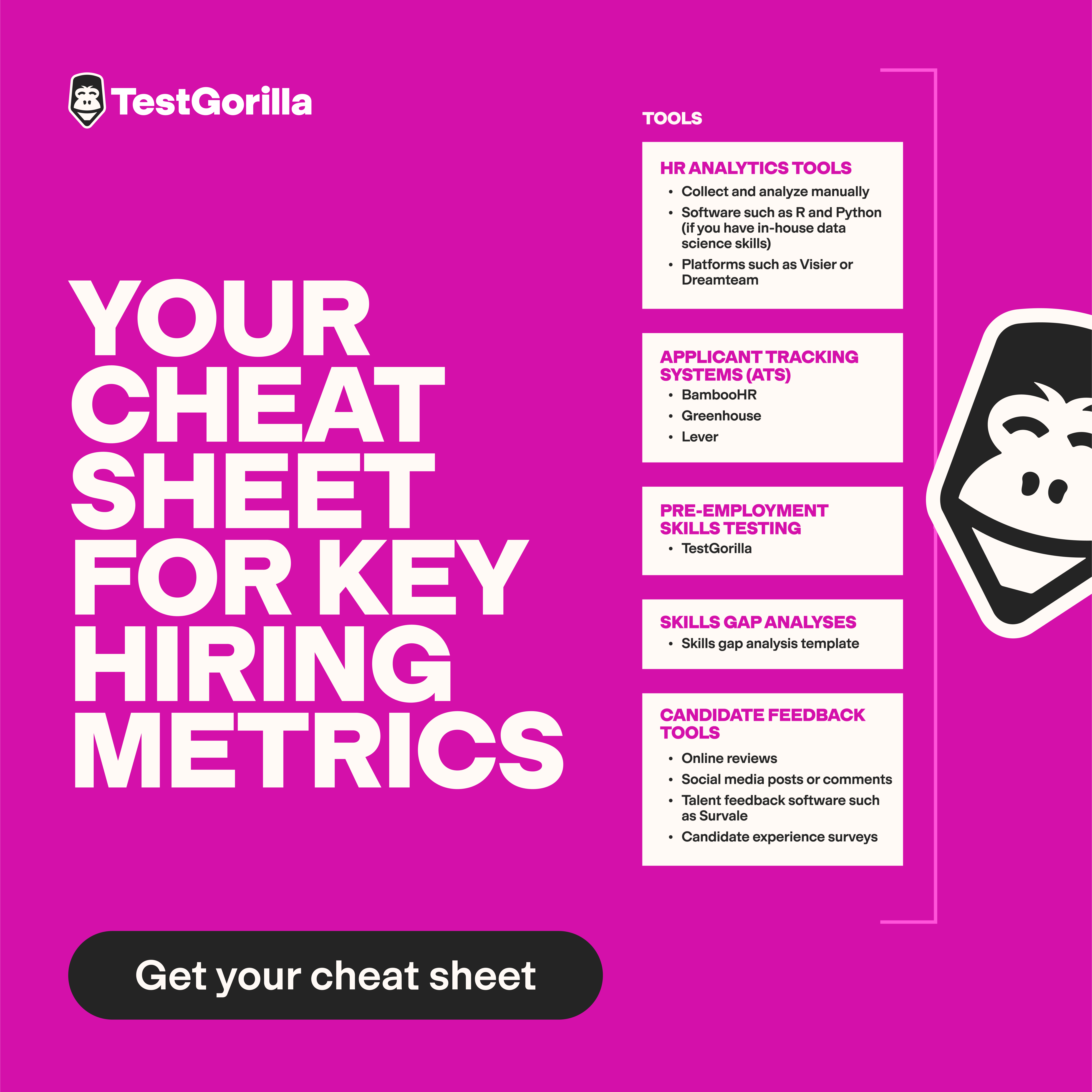

As we mentioned above, you can combine our equipment maintenance technician test with up to four other job-related skills tests from our test library. We included links to tests we thought would be useful to include for this role in the technical and soft skills sections above, so you can use the most relevant ones in an assessment.

Alternatively, you may prefer to browse our test library for yourself, and choose tests from the following categories to include in an assessment for maintenance technician skills:

It’s quick and easy to create a full assessment, even if you’ve never done it before. However, if you want more information, our ultimate guide to creating an assessment (including editing, cloning, and archiving an assessment) is a useful read.

Once you have your candidate assessment results, it’s then a simple matter to choose the best ones to take to the interview stage. And all this is possible without looking at a single CV, which saves you time and effort.

The best insights on HR and recruitment, delivered to your inbox.

Biweekly updates. No spam. Unsubscribe any time.

Find your ideal equipment maintenance technician with TestGorilla today

We hope this article has been useful in showing you how to use our maintenance skills test to evaluate equipment maintenance technician skills. It’s important that you hire only the best candidates for the role, and our data-driven approach makes it much easier to appraise applicants’ skill levels.

Are you ready to swerve the CV pile and join us in forging the future of skills-based hiring?

Great stuff! Sign up for your TestGorilla free plan (it takes less than a minute) to get started on building your first assessment.

If you want more information or to see how our products work first-hand, book a free 30-minute live demo with our sales team, who will be pleased to answer any questions you may have.

Related posts

You've scrolled this far

Why not try TestGorilla for free, and see what happens when you put skills first.