Assess and hire the best reliability engineers

Maintenance and repairs are a must if you’re in the manufacturing industry. Reliability engineers understand performance evaluation and prediction principles to improve your equipment’s effectiveness and maintainability, ultimately lowering production costs.

To hire the best reliability engineer, you need to write a bulletproof reliability engineer job description that identifies their skills, responsibilities, and requirements.

In this article, we discuss what a reliability engineer is, their core hard and soft skills, and how to write a job description.

Let’s take it from the top, starting with “What do reliability engineers do?”

Table of contents

- What is a reliability engineer?

- What does a reliability engineer do?

- Key skills to look for in a reliability engineer

- How to write an effective reliability engineer job description

- Reliability engineer job description template

- Reliability engineer salary

- Next steps: Attract and assess reliability engineers

- Use a reliability engineer job description and skill tests to hire the best reliability engineers

- Reliability engineer job description FAQs

What is a reliability engineer?

A reliability engineer’s role is that of a production specialist who studies the life cycle of equipment and informs businesses on the best ways to manage their assets. Their expertise is crucial for manufacturing companies because they identify and solve potential issues in product development and throughout a piece of equipment’s lifespan.

In particular, equipment failure is almost inevitable because wear and tear is natural, which is why the responsibilities of a reliability engineer are crucial for preventing breakdowns and guiding an organization when they occur.

What does a reliability engineer do?

A maintenance reliability engineer identifies and manages risks that can disrupt business operations and affect reliability. Their responsibilities include asset and risk management and loss elimination.

Reliability engineering is the application of principles, tools, and techniques to ensure a product or system meets or exceeds its specified operational life cycle. As such, reliability engineers focus on preventive maintenance to avoid/reduce failures in a product, machine, or asset. They run root cause analyses to identify problem areas and use statistical data and specialized software to minimize losses.

Reliability engineers also engage in predictive maintenance, which refers to taking proactive, data-driven measures to predict and avoid machine failure. Predictive maintenance avoids unplanned downtime, increasing productivity by 25%.

Sometimes, reliability engineers act as a link between project engineers who create new products and business owners focused on the organization working well and meeting customer demands.

Types of reliability engineers

When you write a reliability engineer job description, you must consider the type you’re hiring. They include manufacturing plant reliability, reliability design, and site reliability engineers. Generally, they work in the production and manufacturing industries; however, the latter works in software engineering and IT infrastructure.

Manufacturing plant reliability engineer: Manufacturing plant engineers identify and mitigate risks related to assets that can affect the operation of your business. These engineers aim to maximize your facility’s uptime while reducing maintenance and production loss costs.

Reliability design engineer: These designers evaluate your product designs and ensure optimal performance. Their role in your company is to plan and execute life tests of your facilities, draft test reports, and mitigate reliability risk.

Site reliability engineer (SRE): They supervise system automation to improve a website’s or software’s performance, ensuring efficiency and scalability by overseeing the entire code deployment of your product.

If you’re hiring a site reliability engineer, then jump to our dedicated piece on job descriptions for SREs because this blog post focuses on manufacturing plant reliability engineers and reliability design engineers.

The best insights on HR and recruitment, delivered to your inbox.

Biweekly updates. No spam. Unsubscribe any time.

Key skills to look for in a reliability engineer

The primary skills of a reliability engineer overlap with those of mechanical and maintenance engineers. However, the skills must also lend themselves to predictive maintenance and failure analysis.

Let’s look at the skills your reliability engineer candidate must possess, which you need to understand before you write your reliability engineer job description.

Reliability engineer hard skills

Hard skills are at the core of the reliability engineer position, and top candidates should be able to prove competence in each of them.

Some are industry-related, but our collection below focuses on transferable technical skills required by all reliability engineers:

Hard skills | Description |

Predictive maintenance | The reliability engineer candidate can analyze and recommend maintenance and replacement programs for a wide range of equipment |

Lifecycle asset management | The applicant understands how long a business can profitably use an asset before replacement and informs the company ahead of time when repair investments are likely to become more expensive than replacement to avoid breakdowns and downtime and improve ROI |

Statistics and probability | The would-be reliability engineer possesses statistical analysis knowledge to proactively seek and identify the maintenance reliability of assets using failure mode and failure rate data |

The job seeker can provide technical support for and understand mechanical, electrical, and systems engineering |

Reliability engineer soft skills

Of course, a candidate’s technical know-how isn’t all that matters. Reliability engineers must also have a number of soft skills – universal power skills that are innate to the individual and time-consuming to develop – to succeed as a team player in your organization.

Soft skills | Description |

Communication | The candidate can effectively participate in the technical and business aspects of the company, convey concepts clearly to third parties without overdependence on technical jargon, and translate customer needs into technical requests for their would-be team |

Problem-solving | The job seeker can find practical and cost-effective solutions quickly and troubleshoot difficult situations with a critical approach |

A reliability engineer should be able to prioritize workloads, stay organized under pressure, and offer support to their team while still making time for their own duties | |

Leadership and team building | The reliability engineer applicant can mentor staff, use delegation, and manage teams to provide feedback and promote continuous development |

Evaluate reliability engineer soft skills

Explore and evaluate reliability engineer soft skills with a free forever account!

How to write an effective reliability engineer job description

You should remember three main things as you write your reliability engineer job description.

Be explicit about technical requirements

Emphasize collaboration

Define the scope

By following these guidelines, you can improve your decision making when selecting candidates who understand the position and your unique requirements based on your needs.

Be explicit about technical requirements

When recruiting for manufacturing positions like reliability engineers, you should be specific about the failure mode and effects analysis (FMEA) processes required, the custom machine specifications you use, and any other technical skills your candidates need to be proficient in.

The more transparent you are about requirements, the higher the chances you attract the right type of candidates with the right type of qualifications.

Emphasize collaboration

Collaboration with other teams is essential for reliability engineers. They often need to work with maintenance teams and project engineers to develop proactive maintenance processes, so sharing your expectations helps them understand your internal team dynamics and develop good working relationships from the start.

Define the scope

You must clearly explain the scope of the reliability engineer’s work. Tell them your precise needs before the job and test whether they’re able to perform, whether it is on routine tasks like data analysis to predict failures or on more complex processes, like troubleshooting performance issues, undertaking root cause analysis to curb failures, or managing critical infrastructure.

Reliability engineer job description template

Below, we look at a reliability engineer job description template. The goal of job postings is to help you answer a question that’s crucial for your candidates to know, “What do reliability engineers do at your company?”

Even if they’re familiar with the role and the job title, they must understand the differences between your position and the other ones on the job market.

Use and customize this template to write the perfect job description for reliability engineers:

Company introduction

Introduce your company. Share its name, industry, vision, and mission, and describe your products. Also, mention any achievements and milestones relevant to a reliability engineer.

Benefits of working with [your company]

Outline your benefits package, including health benefits, training and development opportunities, retirement plans, and unlimited paid time off. Include specific perks you offer, like a flexible time-off policy or benefits for working parents.

Reliability engineer job brief

[Company name]

Job Title: [Reliability engineer]

Reports to: [Operations manager]

Position Type: [Full-time, part-time, or contract]

Location: [On-site, remote, or hybrid]

[Compensation and benefits information]

Reliability engineer responsibilities and duties

Develop FMEA processes for existing and new machines and equipment

Perform data analysis to predict failures and prevent them before they cause downtime

Use performance evaluation tests to find potential safety and production risks

Find recurring failures and perform root cause analysis to understand them and recommend corrective actions

Work with maintenance teams to develop predictive and proactive maintenance strategies that improve equipment reliability

Collaborate with project engineers to maintain and ensure the reliability of new equipment or modified assets and installations

Measure and optimize system performance

Comply with the life cycle management process

Push for continuous improvement and anticipate customer needs

Participate in the development process for the installation of custom machine requirements and specifications

Provide support to production teams to ensure asset utilization and overall equipment effectiveness (OEE)

Reliability engineer qualifications and skills

Required skills and experience

Knowledge of engineering, mathematical, statistical, and data analysis concepts

Ability to multitask and prioritize workloads

Understanding and experience using probability and statistical tools and methods

Data analytics skills

Leadership and logical thinking skills

A bachelor’s degree or master’s degree in engineering, data analysis, statistics, or math

Preferred skills and experience

Knowledge of engineering concepts like risk management, loss elimination, and lifecycle asset management

Familiarity with Computerized Maintenance Management System (CMMS) maintenance software to reduce downtime

Certified Maintenance & Reliability Professional (CMRP) certification

Reliability engineer salary

Now that you’re ready to write the perfect reliability engineer job description, we can look at what your new hire could cost.

The average salary for a reliability engineer is $114,789, with the range typically falling between $106,771 and $123,637 due to varying factors like education, certifications, additional skills, and years of experience.

In hourly wages, this translates to reliability engineers making between $51 and $59 per hour.

The position pays well for a reason. Unplanned downtime can cost manufacturing companies $50bn per year, and it’s far better to pay a high wage upfront for a skilled reliability engineer than incur losses that could amount to many times their salary.

Next steps: Attract and assess reliability engineers

Start by uploading your reliability engineer job description to job websites like LinkedIn or Indeed. Also, ask your employees for referrals or use a specialist recruiter like Elevation Recruitment Group, which specializes in providing maintenance reliability engineer candidates.

Once you post your job description, you need to prepare for the influx of candidates. One thing you need to consider carefully is how to assess their skills.

Manufacturing talent assessments are the best way to ensure your candidates have the hard and soft skills they need to become effective reliability engineers. They trump resumes, cover letters, and other traditional forms of screening because they give you an objective view of each candidate.

Identifying the right candidates for highly skilled technical positions is important because a mis-hire can leave the company shortly after joining, causing instant attrition.

This phenomenon plagued Orbit Technologies, a semiconductor services provider, when it was hiring for highly technical engineering jobs. Once Orbit turned to talent assessments to evaluate candidates, its instant attrition rates decreased by 50%.

Consider the following tests for your reliability engineer candidates:

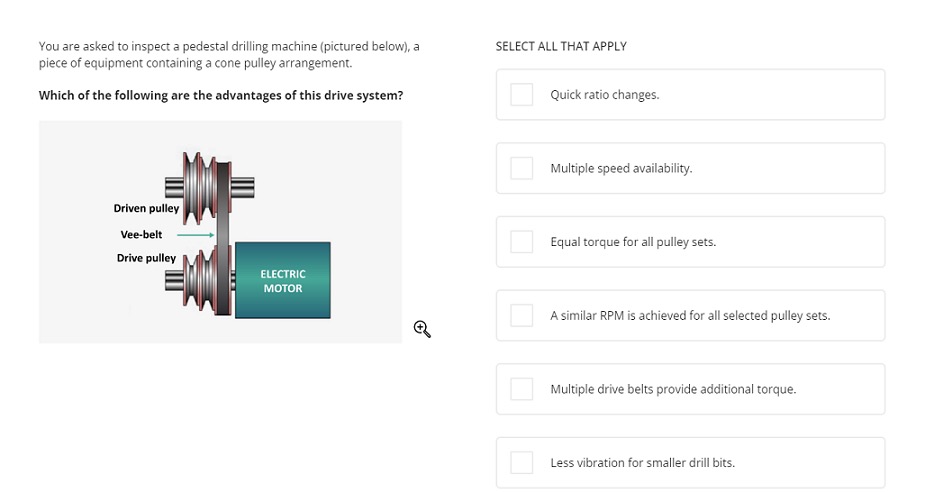

The Equipment Maintenance test is the must-include test because it empowers you to objectively evaluate the candidates’ skills to understand, assess, and implement equipment maintenance.

Our Statistics and Probability test assesses your applicants’ understanding of core requirements for statistical data analysis, including sampling techniques, estimation methods, and inferential and descriptive statistics.

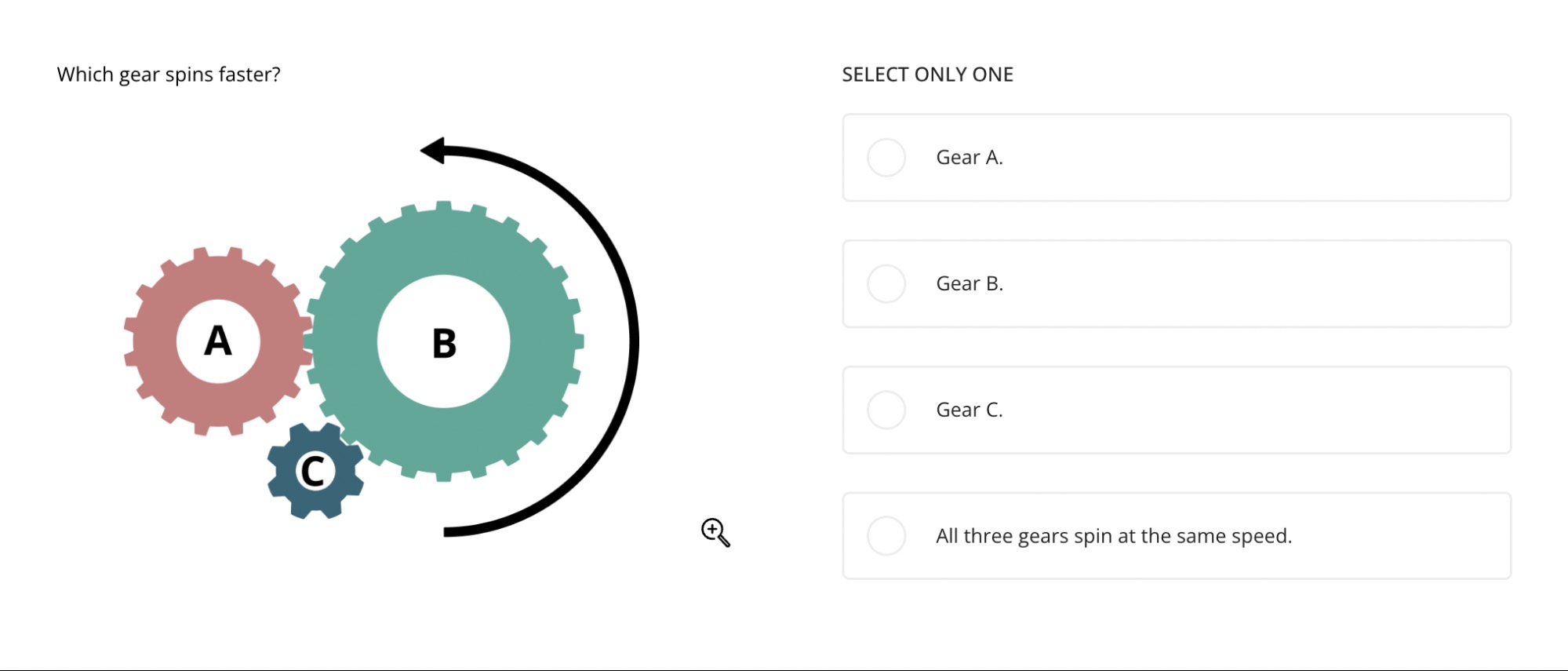

The Mechanical Reasoning test evaluates your would-be reliability engineers’ knowledge of mechanical engineering concepts to help you identify candidates with good mechanical reasoning skills who can use these principles to solve complex problems.

Our Communication Skills test assesses your candidates’ abilities to communicate clearly and effectively, which is an important asset for a person responsible for cross-functional communications with various teams.

Finally, to ensure your applicants’ values and beliefs align with your company, give them our Culture Add test. Once you assess if they are the right addition to your team, you can rest assured you’re hiring a reliability engineer who can grow alongside your company.

After you short-list your candidates, use a structured interview with product-specific questions to understand their personalities and skills better.

Book a free demo

Sign up for a free demo to see how you can assess these skills to hire the best candidate!

Use a reliability engineer job description and skill tests to hire the best reliability engineers

With our reliability engineer job description template, you can communicate your needs to applicants and stand out on job boards.

By using our talent assessments to evaluate the skills of your candidates, you not only attract the best but also easily uncover the reliability engineer duties and qualifications to include in your job description.

Take a product tour to explore how our assessments can help you hire a reliability engineer.

And consider signing up for our free forever plan to get an idea of how much you can achieve with our tests before you invest in a skills-based strategy.

Reliability engineer job description FAQs

Let’s cap off this deep dive into how to write a reliability engineer job description with some frequently asked questions about reliability engineers.

What is another title for a reliability engineer?

Another title for reliability engineer is maintenance reliability engineer. Other names used for this reliability engineering position include maintenance and reliability engineer, equipment reliability engineer, plant reliability engineer, and asset reliability engineer. There are other types of reliability engineers as well (like site reliability engineers), but they don’t work in manufacturing settings and have different skill sets focused on software development.

What is the difference between a reliability engineer and a maintenance engineer?

A maintenance engineer only deals with asset maintenance. On the other hand, reliability engineers participate in the long-term operation of a system or machine. This means that reliability engineers look at the entire lifecycle of an asset, from its installation to its replacement and that these two types of engineers often work together.

What is the difference between a reliability and a quality engineer?

A quality manager’s main purpose is to ensure systems and products meet the quality specifications and standards required by the company or a third-party regulator. A reliability engineer minimizes downtime and ensures the system or machine can operate as needed throughout its lifecycle.

Do you need a degree to be a reliability engineer?

Yes, you need a degree in engineering, math, or statistics. In addition, it’s also highly preferable to have a certified management and reliability professional (CMRP) certification, which is granted by the Society for Maintenance and Reliability Professionals (SMRP). CMRP certification is the only certification program accredited by the American National Standards Institute.

Scroll up to our reliability engineer job description template above for more details.

What is the career progression for a reliability engineer?

Reliability engineers typically follow a career path that leads to more senior positions like project quality manager. This mid-level position can also advance to executive-level positions like plant manager, reliability engineering manager, or director of reliability engineering. Usually, senior-level positions are only open to reliability engineers after they have received their CMRP certification.

You've scrolled this far

Why not try TestGorilla for free, and see what happens when you put skills first.